生意编号39549

最近更新2025年10月06日

27人已浏览

Superpower Booster, Fuel Saver and Emissions Reducer for all Automobile Engines & Generators

高文汽配店汽修店

转让费价格面议

生意转让

寻求投资

合作伙伴

Eden

我要咨询

生意概述

- 物业类型 购物百货中心

- 物业面积 8611尺² / 800米²

- 每月租金 S$6500

- 房租押金 S$1.3万

- 月营业额 一

- 欠款负债 一

- 月毛利润 一

- 月净利润 一

- 库 存 一

- 设施设备 一

- 应付帐款 一

- 应收账款 一

- 卖家职责 全职

- 员工人数 4

- 成立时间 2022

- 发布来源 个人

转让原因

LOOKING FOR INVESTORS AND MARKETING ARM FOR OUR PATENTED PRODUCT

生意详情

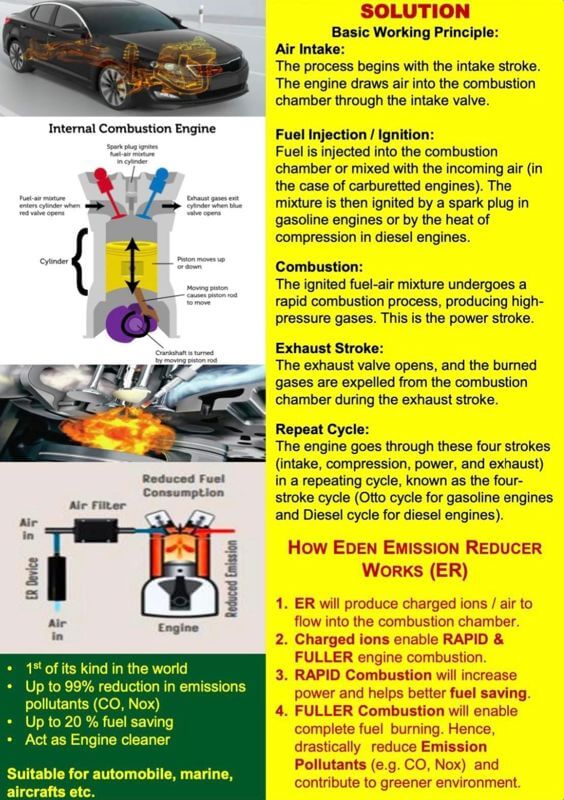

THE PERFORMANCE OF ENGINE AND EMISSIONS WITH CHARGED AIR INTAKE

First in the world, patented superpower booster, fuel saver and drastic emissions reduction in:

Automobiles, boats, ships, generators and any many more internal combustion engines.

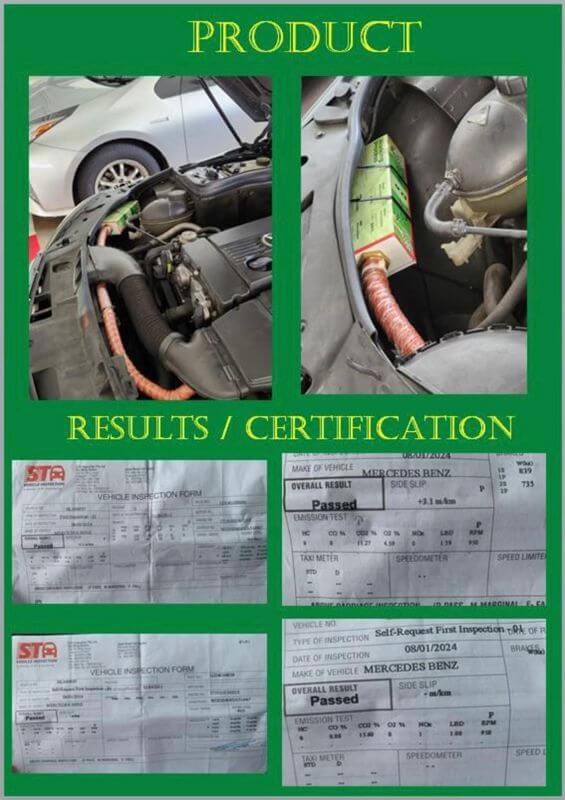

• Up to 20% Superpower increase (Dynamometer force, torque and power tests).

• Up to 20% improvement in fuel efficiency (STA-certified HSU tests).

• Up to 96% reduction in carbon emissions reduction in nitrogen oxides (NOx) (TUV SUD PSB-certified tests)

Product & Technology

How It Works:

1. Charged Ion Injection: Optimizes combustion, reducing unburned hydrocarbons.

2. Fuller Combustion: Lowers CO, NOx, and particulate emissions.

3. Fuel Efficiency: Reduces consumption by up to 20%.

AIR IONIZATION, or the process of energizing air particles to create ions, has drawn interest as a potential method for enhancing engine performance and reducing emissions in internal combustion engines. Air ionization entails the introduction of electric charges to the air intake, which can alter the characteristics relative to the air entering the turbine and potentially influence combustion processes. 02 is the air component most responsible for influencing combustion efficiency, in layman's terms, if the positive and negative ions (0+ and 0-) of the oxygen molecule (02) were balanced, the combustion efficiency would be maximized, while an imbalance would lead to incomplete combustion.

In a nutshell, air carries a lot of dust, floating particles, and other impurities, all of which contain positively charged ions. These ions, along with the air, are then introduced to the carburetor and combustion chamber of an internal combustion engine, where they are combined with fuel and burned. When air with microscopic impurities like dust, microorganisms, and particles carrying a significant amount of positively charged ions is drawn into an internal combustion engine, the conventional air filter is unable to effectively filter out these microscopic impurities.

METHODOLOGY

The majority of methods for lowering automotive emissions, such as catalytic converters and exhaust gas recirculation (EGR), treat the emissions after they are emitted from the engine. These techniques use a variety of processes to transform pollutants into less hazardous compounds or to prevent their development. However, there are also techniques for reducing emissions that aim to avoid their formation at the source, rather than treating them after they are released. One such technique is the use of ionized air during the process of pyrolysis. Ionized air can be used to improve the combustion process by increasing the amount of oxygen existing for combustion, which can lead to more complete combustion and lower emissions of pollutants such as carbon monoxide and hydrocarbons. Most of the available Techniques to Reduce Emissions like Catalytic Converters or EGR tries to Reduce the Emissions after they are released by Combustion. This paper focuses on the development of a device that uses ionized air and through rapid combustion reduce the emissions by avoiding them from the source itself.

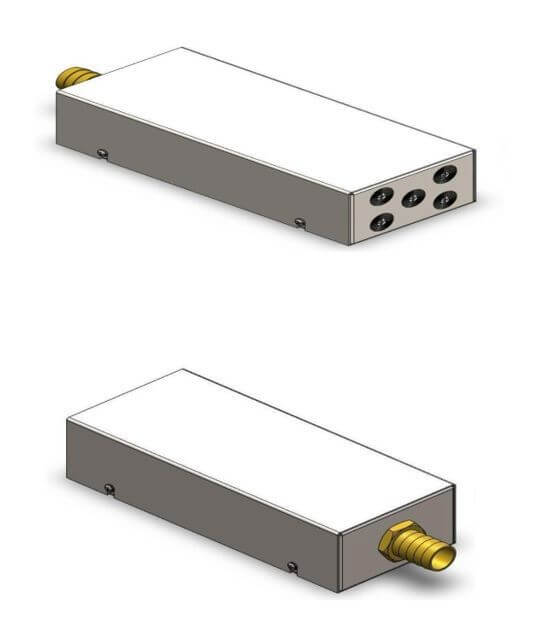

CHARGED AIR INTAKE

As our main focus is on investigating emission control at the source of formation, we have looked at many options, and our work are based on constructing a device that is simple and doesn’t require any engine tuning or changing the design of the components. Our primary objective was to produce a gadget that could be simply placed on both current and freshly produced automobiles. The problem of this strategy to eliminate pollutants at their source is to minimize the production of the cause, i.e., air or fuel purification. We have focused on air purification in order to limit the development of HC, CO, and NOx.

While researching for a simple approach for air filtration, we discovered that several studies have advocated using Processed crystals to purify air. It is thought that Processed crystals, a form of crystal, has air-purifying capabilities. It is frequently used in air purifiers and other air cleaning equipment. The air purification mechanism of Processed crystals is based on the discharge of negative ions, which are atoms or molecules with an additional electron.

Processed crystals is a naturally occurring mineral that exhibits piezoelectric and thermoelectric properties, making it an attractive material for various

technological applications. Some studies have suggested that processed crystals could also be useful for mitigating pollution caused by automobile

exhaust.

The presence of negative ions may decrease the oxygen species that react (oxygen free radicals) generated in the atmosphere by pollutants, nitrogen

oxides, and automobile exhaust, thus decreasing the adverse impacts of too much reactive oxygen species on the human body.

The Processed crystals are put to use right away as a negative ion generator that can generate out a lot of ions with a negative charge. Therefore, a significant number of negatively charged ions mix with a big number of naturally positively charged particles when oxygen-rich air enters the carburetor or injector and combustion chamber, maximizing combustion instantaneously.

Consequently, not only is the power-generating combustion of an internal combustion engine more efficient, However, fuel is used as well more

completely, power is conserved because fewer gallons of fuel need to be used for combustion, and the intensity of post-combustion exhaust emissions is

reduced and enhanced. Notably, despite the fact that Processed crystals have been demonstrated to emit negative ions, its efficiency in air filtration is still being researched and has not yet been scientifically verified. In addition, the effectiveness of Processed crystals in air purification may vary depending on the type of air purifier or equipment employed.

Processed crystals is stored on a corrugated panel that can be easily removed, and a perforated metal sheet is used to prevent Processed crystals from

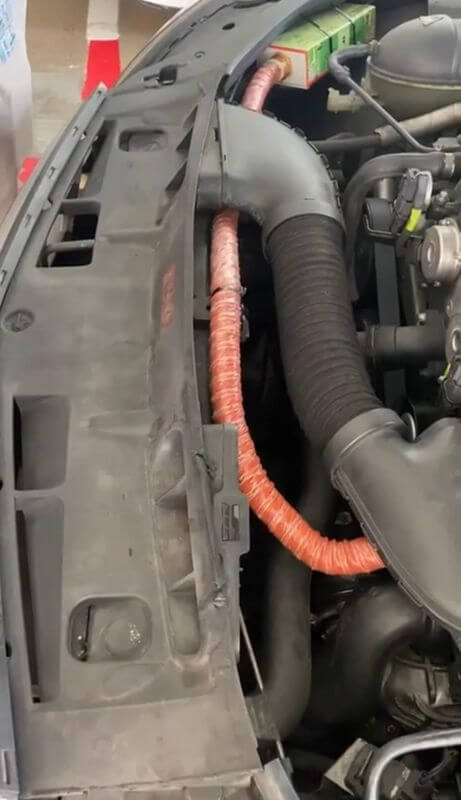

escaping the effective zone. The apparatus was designed to enable the rapid and efficient activation of Processed crystals, which consisted of either vibration or an increase in temperature. Cuts for the air inlet have been provided on one side of the device, and a nozzle has been attached to the opposite side, which is then connected through a pipe to the air intake manifold of the engine.

EXECUTIVE SUMMARY

Internal combustion engines are widely used primarily because of the effectiveness, robustness, and adaptability. These engines provide energy to a variety of vehicles, such as cars, trucks, buses, and airplanes, as well as to machinery and equipment used in the industrial, construction, and agricultural sectors. However, these engines' combustion mechanism results in dangerous pollutants that pose serious threats to both the environment and human health. PM, CO, NOx, and HCs are some of these contaminants.

Several attempts have been put in place to manage and minimize emissions in order to lessen the effects of engine emissions. Such applications use, among other things, selective catalytic reduction (SCR) systems, particle filters, and catalytic converters. Although these systems have been successful in decreasing pollutants, they do have certain drawbacks, such as high costs, high energy usage, and high maintenance needs. As a result, reducing these emissions have become a top priority on a global scale, giving rise to a number of projects to manage engine emissions.

First in the world, patented superpower booster, fuel saver and drastic emissions reduction in:

Automobiles, boats, ships, generators and any many more internal combustion engines.

• Up to 20% Superpower increase (Dynamometer force, torque and power tests).

• Up to 20% improvement in fuel efficiency (STA-certified HSU tests).

• Up to 96% reduction in carbon emissions reduction in nitrogen oxides (NOx) (TUV SUD PSB-certified tests)

Product & Technology

How It Works:

1. Charged Ion Injection: Optimizes combustion, reducing unburned hydrocarbons.

2. Fuller Combustion: Lowers CO, NOx, and particulate emissions.

3. Fuel Efficiency: Reduces consumption by up to 20%.

AIR IONIZATION, or the process of energizing air particles to create ions, has drawn interest as a potential method for enhancing engine performance and reducing emissions in internal combustion engines. Air ionization entails the introduction of electric charges to the air intake, which can alter the characteristics relative to the air entering the turbine and potentially influence combustion processes. 02 is the air component most responsible for influencing combustion efficiency, in layman's terms, if the positive and negative ions (0+ and 0-) of the oxygen molecule (02) were balanced, the combustion efficiency would be maximized, while an imbalance would lead to incomplete combustion.

In a nutshell, air carries a lot of dust, floating particles, and other impurities, all of which contain positively charged ions. These ions, along with the air, are then introduced to the carburetor and combustion chamber of an internal combustion engine, where they are combined with fuel and burned. When air with microscopic impurities like dust, microorganisms, and particles carrying a significant amount of positively charged ions is drawn into an internal combustion engine, the conventional air filter is unable to effectively filter out these microscopic impurities.

METHODOLOGY

The majority of methods for lowering automotive emissions, such as catalytic converters and exhaust gas recirculation (EGR), treat the emissions after they are emitted from the engine. These techniques use a variety of processes to transform pollutants into less hazardous compounds or to prevent their development. However, there are also techniques for reducing emissions that aim to avoid their formation at the source, rather than treating them after they are released. One such technique is the use of ionized air during the process of pyrolysis. Ionized air can be used to improve the combustion process by increasing the amount of oxygen existing for combustion, which can lead to more complete combustion and lower emissions of pollutants such as carbon monoxide and hydrocarbons. Most of the available Techniques to Reduce Emissions like Catalytic Converters or EGR tries to Reduce the Emissions after they are released by Combustion. This paper focuses on the development of a device that uses ionized air and through rapid combustion reduce the emissions by avoiding them from the source itself.

CHARGED AIR INTAKE

As our main focus is on investigating emission control at the source of formation, we have looked at many options, and our work are based on constructing a device that is simple and doesn’t require any engine tuning or changing the design of the components. Our primary objective was to produce a gadget that could be simply placed on both current and freshly produced automobiles. The problem of this strategy to eliminate pollutants at their source is to minimize the production of the cause, i.e., air or fuel purification. We have focused on air purification in order to limit the development of HC, CO, and NOx.

While researching for a simple approach for air filtration, we discovered that several studies have advocated using Processed crystals to purify air. It is thought that Processed crystals, a form of crystal, has air-purifying capabilities. It is frequently used in air purifiers and other air cleaning equipment. The air purification mechanism of Processed crystals is based on the discharge of negative ions, which are atoms or molecules with an additional electron.

Processed crystals is a naturally occurring mineral that exhibits piezoelectric and thermoelectric properties, making it an attractive material for various

technological applications. Some studies have suggested that processed crystals could also be useful for mitigating pollution caused by automobile

exhaust.

The presence of negative ions may decrease the oxygen species that react (oxygen free radicals) generated in the atmosphere by pollutants, nitrogen

oxides, and automobile exhaust, thus decreasing the adverse impacts of too much reactive oxygen species on the human body.

The Processed crystals are put to use right away as a negative ion generator that can generate out a lot of ions with a negative charge. Therefore, a significant number of negatively charged ions mix with a big number of naturally positively charged particles when oxygen-rich air enters the carburetor or injector and combustion chamber, maximizing combustion instantaneously.

Consequently, not only is the power-generating combustion of an internal combustion engine more efficient, However, fuel is used as well more

completely, power is conserved because fewer gallons of fuel need to be used for combustion, and the intensity of post-combustion exhaust emissions is

reduced and enhanced. Notably, despite the fact that Processed crystals have been demonstrated to emit negative ions, its efficiency in air filtration is still being researched and has not yet been scientifically verified. In addition, the effectiveness of Processed crystals in air purification may vary depending on the type of air purifier or equipment employed.

Processed crystals is stored on a corrugated panel that can be easily removed, and a perforated metal sheet is used to prevent Processed crystals from

escaping the effective zone. The apparatus was designed to enable the rapid and efficient activation of Processed crystals, which consisted of either vibration or an increase in temperature. Cuts for the air inlet have been provided on one side of the device, and a nozzle has been attached to the opposite side, which is then connected through a pipe to the air intake manifold of the engine.

EXECUTIVE SUMMARY

Internal combustion engines are widely used primarily because of the effectiveness, robustness, and adaptability. These engines provide energy to a variety of vehicles, such as cars, trucks, buses, and airplanes, as well as to machinery and equipment used in the industrial, construction, and agricultural sectors. However, these engines' combustion mechanism results in dangerous pollutants that pose serious threats to both the environment and human health. PM, CO, NOx, and HCs are some of these contaminants.

Several attempts have been put in place to manage and minimize emissions in order to lessen the effects of engine emissions. Such applications use, among other things, selective catalytic reduction (SCR) systems, particle filters, and catalytic converters. Although these systems have been successful in decreasing pollutants, they do have certain drawbacks, such as high costs, high energy usage, and high maintenance needs. As a result, reducing these emissions have become a top priority on a global scale, giving rise to a number of projects to manage engine emissions.

商业运作

We are now marketing this product. It is expected surely to have high yielding ability.

设施设备

No competition. This product known to be the 1st in the world.

市场竞争

The market expansion is expected to be global.

扩张潜力

物业信息

租赁

物业类型

是的,可搬迁至其它地方。

可否搬迁

是的,可以在家经营。

在家经营

会员专区

我要咨询

请使用英文发送留言

* 您的姓名

▼

* 手机号码

* 电子邮箱

留言详情

所有广告信息均由卖家或其代表提供。我们不对信息的准确性、完整性或真实性进行核实,也不提供任何保证或担保。任何因此而产生的纠纷、索赔或决定,均应由买卖双方自行承担和解决。了解更多 如何避免诈骗。